GREAT news! Sony sensor fab struck by earthquake will be back online soon

posted Friday, May 13, 2016 at 2:49 PM EDT

If you've been watching the situation in southwestern Japan in the aftermath of the recent Kumamoto earthquakes with the same level of concern we've had (and we've been very concerned), then we have some really GREAT news to share with you today! In its fourth update on the situation at its facilities which were affected by the quake, Sony has just reported overnight (US Eastern time) that production at the Kumamoto Technology Center operated by Sony Semiconductor Manufacturing Corp. should resume very shortly.

Given that essentially all the major camera manufacturers either use Sony sensors directly, or rely on the Sony fab line to manufacture their own sensor designs, and all of that work happens at this one plant in Kumamoto, damage there has had a cascading effect on the camera business. So news that they're about to get this plant up and running again has given us some much-needed peace of mind as we head into our weekend. And if you've been waiting to get your hands on a new camera (or have just been concerned about the financial stability of your favorite camera brand) then it should do the same for you.

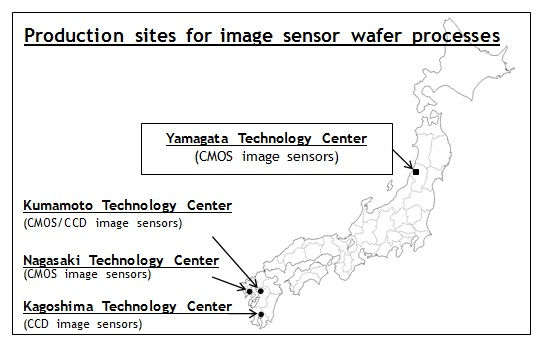

If you've not been following the situation, a quick recap would probably be helpful. The Kumamoto region of Japan was struck by two earthquakes on April 14th and 16th of this year, the former of magnitude 6.2, and the latter of magnitude 7.0. Those are big enough, but they were very shallow quakes as well, so they produced much more ground movement than we'd normally associate with those magnitude numbers. Together, the quakes caused significant damage and loss of life, with at least 49 people killed, thousands more injured, and many buildings damaged. (Even thee days after the second quake, 180,000 people were still homeless.) Among the damaged facilities were Sony's Kumamoto and Nagasaki Technology Centers, which supply image sensors for all manner of products from smartphones to standalone cameras and more.

Damage at the Nagasaki center that supplies smartphone image sensors was relatively minimal, and that facility resumed operations quite quickly. The Kumamoto center was much closer to the quake's epicenter, however, and the impact significantly greater. The plant has been offline for the last month, and without the supply of image sensors it would have produced in that time, numerous companies have had to reevaluate their product plans. (As noted, this single factory produces a significant percentage of the sensors used by major camera companies.)

It's hard to say precisely which product delays are attributable to the quakes, given that camera makers often don't disclose the source of their image sensors. It's worth noting, though, that we've seen delays to quite a few products which had already been announced of late -- most notably from Nikon -- as well as rumors of delays for further products which haven't yet been publicly announced. (We don't generally report on rumors here, so haven't covered those; if we're aware of specific products, we're typically under a non-disclosure agreement which prevents us from doing so, and if not, then it's hard to know how much credence to give these stories. In this situation, though, these rumors do fit the overall picture, so they're fairly believable.)

And those delays have continued, sometimes rather quietly. For example, Sony Alpha Rumors reported today that the Sony A68 -- initially planned to ship last month -- has just been delayed until August 4th at numerous retailers. We've independently confirmed this new date with IR affiliates Adorama, Amazon and B&H Photo Video.

Hopefully now that Sony has resumed testing operations at the Kumamoto Technology Center, with assembly processes expected to resume beginning May 17th and wafer processing as of May 21st, we'll see an end to new product delays. That will leave us breathing a huge sigh of relief, as the more products that were delayed, the greater the financial impact on the industry as a whole. An excerpt of the relevant portion of the statement from Sony follows below:

May 13, 2016: The status of Sony Group business operations affected by the earthquake of April 14, 2016 and subsequent earthquakes in the Kumamoto region, as of today, is as follows:

-

Operations at Sony Semiconductor Manufacturing Corporation's Kumamoto Technology Center (located in Kikuchi Gun, Kumamoto Prefecture), which is the primary manufacturing site of image sensors for digital cameras and security cameras as well as micro-display devices, had been suspended due to the impact of the earthquakes. However, as of May 9, 2016, testing operations, which are one of the back-end processes carried out on the upper layer of the building, have resumed and other back-end processes, such as assembly, are also expected to restart sequentially beginning May 17, 2016.

-

Wafer processing operations located on the lower layer of the building are expected to restart sequentially beginning May 21, 2016.

-

Although there was a delay in the supply of components to Sony from certain third-party suppliers that also have manufacturing facilities in the Kumamoto region, inventory adjustments have been made and a timeframe for regaining supply levels is now in place, so no material impact is anticipated on Sony's business operations.

We're not out of the woods quite yet, obviously, and we'll be eagerly awaiting more news -- hopefully positive -- from Sony and other affected companies. There does finally seem to be some cause for optimism, though!

(via Image Sensors World)