A geek’s tour of Sigma’s Aizu lens factory: Precision production from the inside out

posted Thursday, September 19, 2013 at 2:50 PM EDT

On a trip to Japan this past August, Sigma Corporation's CEO Kazuto Yamaki asked if I'd like to tour their factory in Aizu Wakamatsu. Engineer/geek that I am, I couldn't possibly resist. Sigma Corporation has been a leading player in the third-party lens business since there was a third-party lens business. Long seen primarily as a source of inexpensive add-on lenses, they've recently been reshaping themselves into a purveyor of true high-end, no-excuses glass that's in the top tier of optical performance. (In our recent SLRgear review, we called the new Sigma 18-35 mm f/1.8 DC HSM "A" "by a wide margin, the best constant-aperture/wide-aperture zoom lens we've ever tested".) With this as background, the opportunity to have a true no-holds-barred geek's tour of their factory was a chance not to be missed.

So it was that I found myself on a short flight from Osaka to the Fukushima airport, where I was met by Shinji Yamaki, Sigma's manager of European marketing. A pleasant 90-minute car ride through the mountainous countryside brought us to the Sigma factory in Aizu. The Aizu site has been home to Sigma's manufacturing from very early on, only a few years after Kazuto-san's father founded the company. Aizu is an interesting region historically, with a somewhat sad tale of betrayed loyalty to the Emperor during the Civil War period, which led to a long period of relative isolation from the rest of Japan. In some part, that isolation and the culture it produced is what led to Sigma locating their factory there.

In the early days of Sigma, Michiharo Yamaki (Kazuto-san's father, and founder of the company) faced stiff competition for skilled workers in the Tokyo area, as it was then the boom time of the Japanese optical industry, with not enough skilled workers to go around. Through a worker from the Aizu region, Michiharo-san learned of the local population's reputation for diligence and ability to concentrate on fine details. A recruiting trip to the area led to a particular night that involved a great deal of sake, in which the local farmers pressed Mr. Yamaki to build a factory in the area. They were hoping for jobs that they could work at in between their agricultural duties. In a moment of inebriated agreeableness, Michiharo-san half-jokingly said "sure, I'll build you a factory." The next morning, he discovered to his dismay that, while he had been joking, the farmers were completely serious. After a not-insignificant amount of badgering, Mr. Yamaki relented, rented a single room in someone's home, stuck a metal lathe in it and hired a person to run it. That was the beginning of Sigma's manufacturing in Aizu.

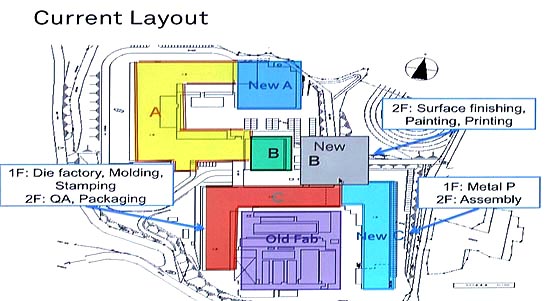

Mr. Yamaki soon learned that the citizens of Aizu had an exceptional work ethic, and an unusual capacity for maintaining focus on details that would be mind-numbing for more ordinary folk. One thing soon led to another, culminating in construction of the first building in Sigma's current complex in the early 1970's. Today, that original building has been added onto a number times, with total area across all buildings now totaling more than 50,000 square feet of high-tech manufacturing space. That's a bit over one and a half American football fields, most of it densely packed with manufacturing equipment. It's a seriously impressive operation. The diagram above shows the overall layout.

One of the things that's remarkable about Sigma's manufacturing operations is the extent to which they're vertically integrated: Almost all production steps for their lenses occur in-house, including lens grinding, aspheric lens molding, metal machining of lens barrels and other components, injection molding -- including making their own injection dies -- optical coating, final assembly, and more.

Besides its sheer scale, the other thing that immediately impressed me about the Sigma factory was how clean it was. Especially remarkable for a lens-manufacturing operation, where the polishing process involves slurries of polishing compound and glass residue, the Sigma plant was absolutely spotless, from top to bottom. Even aisle space right next to the polishing machines themselves looked like you could eat from it. (Sushi, anyone?) It may not matter much to the polishing process itself, but the attention to cleanliness throughout spoke to me of a degree of meticulousness that was evident at all levels of the operation.

Optics production

As you'd expect, lens manufacturing begins with grinding and polishing raw optical glass into lens shapes. At Sigma, this occurs in three stages for conventional (non-aspheric) lenses; CG or curve generation, smoothing, and polishing. Aspheric elements are formed by pressing the glass in precision molds at high temperature.

The CG machines pick circular glass blanks out of trays, press them against a rotating spindle with a grinding head angled and shaped to produce the desired profile, then return the ground blanks to the tray. The shot above shows the input side of a CG machine, with the mechanical arm having just picked up a fresh blank from the tray. (It's the white disc you see suspended from the arm just right of center.)

Here's a look at the business end of that same CG machine. The glass blank is mounted on the end of the white spindle at center (the one with the grey-colored coupler between the two white pieces. The grinding head is inside the white box at right, apparently housed that way to contain the spray of coolant with glass dust suspended in it.

The shot above shows a "smoothing" machine; think of this as a fine-grinding operation. It uses a finer grit than the CG machine, removing scratches left by the CG machine, but doesn't significantly change the curve shape.

The final step is polishing, carried out on machines like the one shown above. This machine is designed to polish large-diameter lenses. The particular machine shown in this shot is producing a concave profile on several lenses. Polishing "fine tunes" the lens shape, taking the shape produced by the preceding combination of curve generation and smoothing, and bringing it to its final shape. In many cases, polishing is a process of progressive refinement, with some lenses receiving as many as three or four polishing operations. (Note how spotlessly clean the floor is here, even immediately adjacent to the machine. I've seen other lens-grinding facilities, but never anything approaching this level of cleanliness.)

You'd expect lens production to involve lots of polishing, but the sheer scale of it is pretty amazing. The shot above shows about half of one room of polishing machines. There's another entire room of these machines, perhaps twice as large as this one, so what's shown here is less than 20% of the total polishing capacity in the Sigma factory.

Conventional polishing operations can only produce lens profiles that are sections of a sphere. Aspheric lenses help lens designers eliminate spherical aberration, and also make lens systems much more compact, in many cases replacing a complex, multi-lens assembly with a single element. While it's possible to grind and polish an aspheric surface, it's vastly more efficient to mold it. Machines like the one above do this, pressing pre-formed glass blanks into ultra-precise molds made of refractory metals (tungsten or similar), at elevated temperatures. This is an incredibly tricky process, as the stresses and distortion of the glass as it moves through the temperature cycle need to be taken into account, and the final surface geometry needs to be controlled with sub-micron accuracy. There isn't an awful lot to see in the shot above, as everything happens inside an enclosure, with the lens passing through multiple heating/cooling zones. (I thought I had a wider shot of one of these machines, but couldn't find it on my SD card.) As with everything else in the Sigma factory, there's a huge roomful of these machines. Quite an investment at a cost of about $300,000 - $400,000 each!

After the lenses are ground, the very important step of "centering" is performed. The lenses are clamped in precisely-contoured jigs, spun on a lathe-like device, and the edges are ground by a rapidly-spinning head, running in an oily coolant liquid. An air-handling system connected to each machine vacuums away the coolant mist, but a very small amount still escapes, making the floor in this area a little slippery. (This was the only part of the factory where there was any hint of a foreign substance on the floor.) When they leave the centering machine, the lenses are in their final shape, with smooth, beveled edges concentric with the lens' optical center.

As with the polishing machines, there's a huge roomful of centering machines whirring away. The shot above shows a fraction of the total.

There was a lot of evidence of quality control and checking of the various components within the plant. Here, a worker is checking individual lens elements to ensure that they've been ground to the correct profile. The instrument he's using projects a laser light source through the lens and bounces it off an optical flat. (Actually, I'm not sure whether it's a flat or an optical surface with a profile polished into it.) The resulting interference pattern (for photographers with darkroom experience, think "Newton's Rings") shows whether the profile is correct or not.

Coating is the final optical step for the individual lens elements. Optical coatings reduce internal reflections in complex lenses, reducing flare and ghosting in your images, and improving contrast. The polished lens elements are loaded on big carousel discs, which in turn are loaded into huge vacuum evaporation machines. The shot above shows a worker loading the polished, centered lenses onto one of these carousels. I was surprised to see the workers handling the lenses without gloves, because finger grease would be death to either a high-vacuum system or the coatings themselves. It turns out they're wearing thin, transparent plastic sleeves over their fingers, rather than gloves. I imagine these provide much better dexterity, and mean that the workers don't have to work with their entire hands in latex or neoprene gloves all day.

My apologies here, though - I neglected to get a shot of the vacuum evaporators themselves. They were pretty obscured through a window, though, so wouldn't have been a great shot anyway. They're huge machines, with a large, central high-vacuum chamber that always stays pumped down, and airlocks on either side of it. A carousel is loaded into the left airlock, it's pumped down to high vacuum, then the carousel is slid over to the evaporation chamber. The coating material sits in the bottom of the vacuum chamber, where it's heated to the evaporation point, usually by either a tungsten filament or an electron beam. (I didn't ask, but as far as I know from prior experience in the semiconductor industry, big production machines like this are more likely to use electron beam technology.) Since there aren't any air molecules to get in the way or react with the evaporant, the molecules or atoms fly in straight lines, and are deposited on the lenses in the carousel. The carousel rotates during the deposition process, to make sure the coating is deposited evenly. Mr. Yamaki-san told me that the evaporators were the most expensive machines in the factory, costing about a million dollars apiece.

Metalworking

While all this has been going on with the lens elements themselves, the lens bodies have been taking shape in other parts of the factory.

There are a lot of metal components in Sigma's lenses, so there's quite a bit of manufacturing capacity devoted to machining, with rooms full of vertical machining centers of varying degrees of capability. The shot above shows a huge, multi-axis machine. The most sophisticated units are so-called 9-axis machines. (I'm not sure if the one above is one of these or not.) The 9-axis systems can basically position a part at any angle relative to the three coordinate axes, can have the milling cutter approach at any angle, and also have the ability to spin the part to do lathe operations. To give you an idea of scale, the machine above is about 15 feet long, 14 feet wide, and 12 feet high. From the look of it, it's been making some base plates for injection molding (the metal rectangles with many holes in them at the bottom and left of the frame.)

Here's a view looking down about half of one room of vertical machining centers. The machines are two deep on each side of the aisle. I have no idea of the exact count of the machines in this room, but would guess there are somewhere between 50-100 of them, of various types.

Here's the output end of a machine making lens mounts. The shiny pieces in front are the finished parts, the dull golden ones in the background are the raw, die-cast blanks. You can just see the robotic arm at upper left that loads and unloads the machining center, which is out of the picture, to the left.

Not everything is CNC-driven -- some operations are still performed manually. This gentleman is running a manual lathe, turning some sort of flanged tube from aluminum stock.

Some very hard/tough alloys are difficult to machine with conventional cutting tools. The electrical discharge machine (EDM) above is one solution to that problem. Dies are made in the shape of the metal that's to be removed, loaded into a head that travels up and down, and both die and part are submerged in an insulating liquid. High voltage/high current electricity is applied to the die, and the machine lowers it onto the part. At some point, an arc will jump from the die to the part, eroding metal wherever it hits the raw stock. Every time an arc is struck, the machine pulls the die back a little, then advances it again to strike another arc. The fine metal particles removed from the part are carried away by the recirculating dielectric fluid.

It's a laborious process, but has the advantage that it doesn't matter in the slightest how hard the stock being machined is; if it conducts electricity at all, it can be machined.

Sigma also operates a number of wire discharge machines, which operate on a very similar principle, but the working electrode is a string of wire, stretched taut between a pair of electrodes. These machines are basically used like giant jigsaws, cutting through sheets of tough metal from top to bottom, sectioning them or creating edge profiles. The wire is fed through the machine continuously, so erosion of the wire doesn't affect the kerf width. As you might expect, wire EDM machines use a lot of wire. The wire exiting the machine is chopped into fine pieces and sent in bulk to metal recyclers.

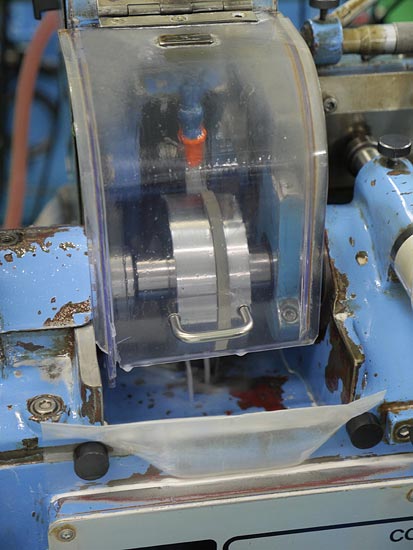

Did you ever wonder where screws come from? Some are stamped, but the better ones come from machines like the one above, called, appropriately enough, screw machines. This is the back end of one, with a bar of feedstock running into the maw of the machine, towards the top middle of the frame. Operation is completely automated; once programmed, the machine will happily digest bar after bar of raw stock, with the finished screws tumbling out in a flood of coolant on the other end, to be caught in a steel-mesh strainer.

Here's the finished output of one of the screw machines. The shot at left shows a batch of finished screws, caught in the strainer that separated them from the coolant. The shot at right shows a couple of them in Yamaki-san's hand.

As you'd expect, Sigma purchases a lot of their screws from suppliers, wherever a standard configuration can be used. In many situations, though, only a custom fastener will do, so Sigma keeps a bevy of screw machines pretty busy.

After metal parts have been fabricated, they go the surface finishing area. Surface finishing may include painting, bead-blasting, plating, or anodizing. The shot above shows a portion of the anodizing operation, where aluminum parts are dipped into acid baths and current passed through them to create a layer of super-hard aluminum oxide on their surfaces. Once the oxide is created, it can be dyed to whatever color is desired, and then passivated in a process that closes the pores in it, so it'll be impervious to staining out in the field. The anodizing room was hot, humid, and generally unpleasant. Excellent ventilation meant there was no hint of chemical smell or fumes, despite the large tanks of acid bubbling away. Still, my hat's off to the workers who labor there.

I was surprised that some parts of the process that I'd assumed were probably automated were actually manual. In the shot above, the worker is injecting paint into engraved/recessed letters on bezels for AF/MF switches. I had expected that this sort of lettering would involve something like a squeegee blade passing over the recessed letters, depositing white paint in its wake. Thinking about it, though, that would be tough to make work, given that the part here has other recesses that would collect the paint, as well as the lettering it was intended for.

The "painting" being done here is interesting too, in that it doesn't involve a brush. Rather, the worker is wielding something that looks like a hypodermic syringe, minus the plunger. Paint is supplied continuously through a tube, and injected down a narrow tube that the worker uses to fill the recessed lettering. Every part looked perfect, I can't imagine sitting there 8 hours/day doing this. Hats off to this worker, too...

Plastic fabrication

Leaving metalworking for a bit, we'll turn to plastic fabrication, specifically injection molding.

As the name suggests, injection molding consists of injecting the raw material in a molten state and under high pressure, into precisely-machined molds. Chances are that every piece of consumer electronics or household appliance in your home has at least one injection molded part somewhere inside it. In modern photo equipment (cameras and lenses both), a majority of the structural elements are injection-molded.

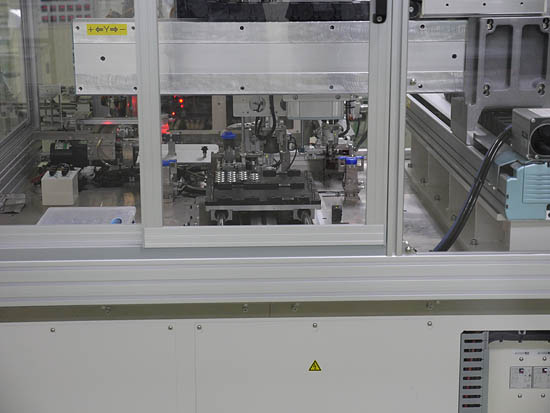

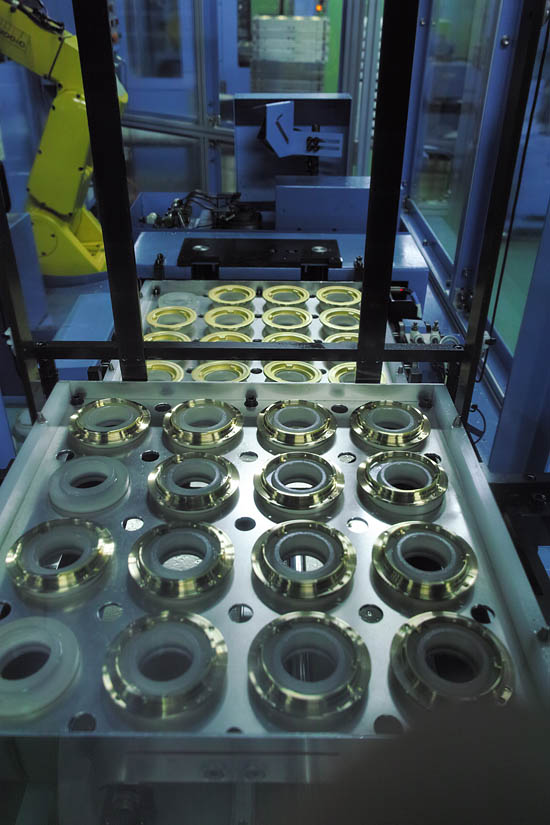

Injection molding has the advantage that it can hold very tight tolerances on parts, yet the incremental cost of production (the per-part cost, once the molds are paid for) is very low. The shot above shows one of the huge injection-molding machines, with a tray of finished parts in the foreground. A robotic arm (very top/center of the frame; the grey thing projecting downward) removes parts after molding, clips and removes the sprues (extraneous pieces of plastic, from channels used to carry the molten plastic to the interior of the mold) and drops them in the output bin.

Having always associated plastic with cheap construction, I was surprised to learn that Sigma's injection-molded parts are actually considerably more precisely dimensioned than their metal counterparts. This is because, once the master mold has been created, there's essentially zero wear from part to part, so consistency is extremely high. By contrast, when machining metal, the cutters are always subject to wear, in ways that's hard to compensate for -- even with CNC machine tools.

This shot is a closer view of the parts exiting the machine above. These are actually pretty simple compared to many of Sigma's injection-molded parts (some can be very complex), but even here, there's a lot of detail that would require a lot of machining time to create. What's great about injection molding is that even the most complex parts can be cranked out like jellybeans, once the molds have been made.

In earlier days, plastic parts in lens assemblies were an issue because the thermal expansion properties of the plastic were different from the aluminum parts surrounding them. At high or low temperatures, tolerances could shift, parts could bind, or optical quality could suffer due to poor alignment of elements. Addressing this, Sigma has developed what they call Thermally Stable Composite ("TSC") plastic, which has the same coefficient of thermal expansion as aluminum. Composed of a mixture of polycarbonate resin, glass fiber, and metal fibers, TSC not only matches the thermal characteristics of aluminum, but is considerably stronger and more elastic than conventional glass-loaded polycarbonate formulations. The improved mechanical characteristics mean that parts can be made smaller, while retaining the strength and toughness of their larger predecessors.

Injection molding can also combine plastic and metal parts into a single assembly. The parts shown above have three metal tabs that are molded right into the plastic. The machine that inserted the tabs into the mold cavity was quite clever in how it picked up and precisely arranged the metal parts, but Mr. Yamaki was understandably concerned about me videotaping within the factory, so I don't have a movie to show you of it. (I greatly appreciate the access Mr. Yamaki gave me for the still shooting: It's very unusual to be allowed the level of access and freedom to photograph that he extended to me on this tour.)

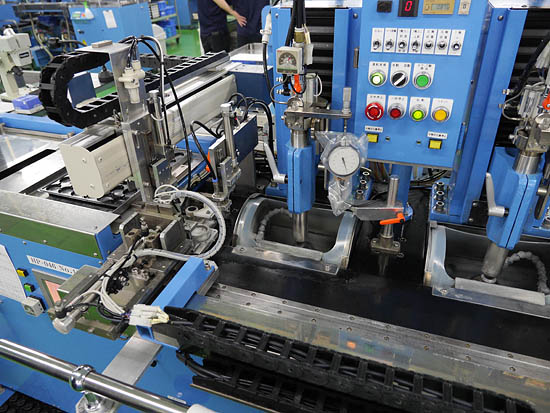

Here's a surprising stat: Sigma says they can maintain dimensions to less than +/- 1 micron on their injection-molded parts. (A micron is one thousandth of a millimeter, about 39 millionths of an inch.) Of course, in order to produce parts to those kind of tolerances, you need to be able to measure them that accurately as well. That's the job of the machine above and its sibling in the background. A ruby-tipped stylus can trace the outlines of a part, measuring to an accuracy of less than a micron, anywhere within what looked to be a working volume of a meter on a side.

Sigma is unusual, in that they maintain their own mold-making shop. Molds (actually called "dies" in the trade) are massive blocks of high-grade stainless steel, with cavities in them the shape of the parts to be made. Mold-making (at least to the tolerances required for lenses) is an exacting, iterative process. A major obstacle is the thermal properties of the plastic itself. As the plastic cools from its melting point, it shrinks considerably. The size you want is obviously the size it will be when it's cool, but that has to be a good bit smaller than the size of the cavity in the mold.

The CAD software used to design the molds can compensate for thermal expansion, but it's a highly complex situation, with different regions of the part shrinking more or less, depending on how thick they are, what stresses are acting on them from adjacent regions, etc.

So, while CAD will get you most of the way there, there's ultimately some amount of trial and error involved. (Noting that "error" here means a dimension off by a few microns.) Successful mold making often requires two, three, or even four iterations, with molds made, parts cast and then measured on the behemoth measuring machines shown above. Any discrepancies are recorded, a new mold is made, new parts cast and measured, and the cycle continues.

As you might expect, this is an expensive process. The molds have to be machined to incredibly tight tolerances, carved from a very tough stainless-steel alloy. Surface finish is also critical, which adds considerably to the difficulty and time required for the machining process.

As expensive as it is to maintain their own mold-making shop, Mr. Yamaki said that without it, the development costs for many new lenses would be simply prohibitive. Development cycles would also be considerably lengthened, to accommodate parts shipping to/from die-making companies, scheduling with those vendors, etc. By keeping the mold-making in-house, costs are reduced and iteration cycles are shortened, so Sigma can produce more and better lenses each year.

Once the plastic, glass, and metal parts have all been fabricated, the next step is assembly. This is essentially a manual process, because it's important to inspect each lens element to make sure there are no minute flecks of dust on it that would interfere with the lenses' mating properly with each other. Note the "bunny suit' the worker above is wearing: All optical assembly is performed under clean-room conditions. The nylon suit prevents things like loose hairs or shed skin cells from contaminating the optics. The air in the clean-room assembly areas is also filtered to remove dust particles. Each assembly workstation has a bright light that the workers use to inspect the lenses, ensuring that no dust or other contaminants are present on the surfaces of each lens element.

The worker above is assembling lens elements into an optical group. A small drop of adhesive is placed between each pair of lens elements to hold them together. The adhesive is completely fluid until the assembly is exposed to UV light, which hardens the resin and bonds the elements together.

There's an intermediate step between optical-group assembly and final assembly of the completed lens, which I don't have documented. That's edge-painting, where the rims of the lenses and optical groups are coated with flat black paint, to reduce internal reflections. This is a manual process, with workers applying the black paint with a brush.

Final assembly and testing

Once all the optical groups, metal, and plastic parts are finished, it's time for final assembly of the finished lens. The shot above shows a final-assembly station. I don't know what lens was being assembled here, but from the look of the unit that's on the work surface (just to the left of the worker), it's probably some sort of wide-angle prime.

When everything has been assembled and the lens is complete, the final step is testing. Testing and QC have always been key parts of Sigma's process, but there's been a recent & significant upgrade in this area. For a long while now, Sigma has spot-checked lenses on an MTF tester of their design, which employed a Kodak image sensor. As digital SLRs and CSCs have evolved to ever-higher resolutions, though, the old system began to show its age, in that it wasn't able to discriminate critical focus as well as some of the camera systems Sigma's lenses were being used on.

Searching for a better solution, the Sigma engineers had an epiphany when they realized that they already had an excellent, very high-resolution sensor at their disposal -- namely the Foveon chip used in their flagship SD-1 camera. The only catch was that that sensor was an APS-C sized one, smaller than the full 35mm frame that many of Sigma's lenses cover.

The solution, of course, was to cover the frame piecemeal, using four individual, overlapping exposures to achieve full-frame coverage. One of Sigma's clever young engineers developed a combined software/hardware solution that did this (sorry, I didn't get the engineer's name; he surely deserves credit), the result being Sigma's new A1 MTF-measuring system. A housing encloses the sensor assembly and the motorized stage that moves the sensor either successively to the four corners of a full-frame area, or to the center of the frame, for testing lenses designed for cameras based on either APS-C or Micro FourThirds sensors. A universal lens-mounting system on the front of the housing accommodates lens mounts for Sigma, Canon, Nikon, Pentax, Sony (both A- and E-mount) and Micro Four Thirds systems, precisely matching the flange-sensor distance spec for each.

Unfortunately, I wasn't allowed to take photos in the area where the A1 systems were being built and used; the work being done there was a bit too proprietary for public dissemination.

What's particularly remarkable about the new A1 MTF-testing systems is not so much the systems themselves (which are exceptional enough in their own right), but the way they're being used. All of Sigma's new "Global Vision" lenses are being tested 100% on A1 systems, with any that don't pass muster across the entire frame being rejected. As far as I can tell, this is an unprecedented level of QC for the lens industry, and sample variation among the new Global Vision optics should be dramatically lower than we've seen thus far from the industry as a whole. The engineer behind the A1 system has built 30 of these systems to date, for use in production testing, with more in the pipeline.

Mr. Yamaki noted that the new A1 testing system gives them a much finer ability to discern minor variations in sharpness, and smaller amounts of decentering of a lens' elements. Sigma's lens designs have always been characterized by much better than average sharpness at a given price point, but the new A1 testing system ensures that all of the Global Vision lens models will perform closer to design specs than has previously been possible. Mr. Yamaki said that using the A1 system and the more stringent quality controls it enables has reduced their manufacturing yield somewhat, but he's happy, knowing that they're producing lenses with an unprecedented level of quality and consistency.

Take a video tour

While he gave me unprecedented access to the factory floor, and permission to shoot stills there, Mr. Yamaki-san was understandably reluctant to do the same with video. Sigma themselves have produced a film about the Aizu factory, though, and it's easily the most beautiful factory-video I've ever seen. (The Aizu area of Japan has impressive scenery and lots of natural beauty.) When you watch the video, you may recognize some of the factory areas and processes described in the article above.

Sigma's hospitality

Mr. Yamaki and Sigma were also exceptionally gracious hosts during my visit. After touring the factory, they treated me to dinner at the very traditional (and excellent) Ashina Ryokan in Aizu. Ryokans are traditional Japanese inns, originating in the Edo period of Japan (1603 - 1868) as lodging for travelers along Japan's highways. Many modern ryokans have been westernized to a fair extent, but Ashina is very traditional, with tatami-matted rooms, no furniture but low tables and floor-chairs, and a traditional onsen (communal, segregated by gender) bath. The lack of a conventional bed caused me a little consternation when I arrived after a long day of travel and wanted to lay down - no problem, though, I just gathered the cushions from four of the floor-chairs and lay down on those. :-)

While we were at dinner, Ashina's staff set out traditional futon bedding for us in our rooms. Spread on the floor, the futon mattress was quite firm, but I found it comfortable, and slept well. (Helped, I'm sure, by the prodigious quantities of sake I had with dinner.)

Ryokans distinguish themselves by their food, and the food at Ashina was really exceptional. I honestly don't care for a lot of Japanese fare, finding it rather bland, despite its freshness. The food at Ashina was very different. Cooked over an open charcoal fire by a gracious and accommodating young woman named Alona, it was truly delicious. Alona was a wonderful hostess, and it was nice that she spoke such excellent English, so I actually knew what I was eating - not always a given for me in Japan. The service at dinner that night was some of the best I've ever experienced in a restaurant: Alona was constantly and almost invisibly attentive to our needs; we never had to ask for anything, it just appeared when we needed it. It's a shame that Japanese tradition forbids tips, she certainly would have earned a generous one by American standards. (Maybe Ashina's owners will read this, though, and give her a raise ;-)

The shot above shows the first course of our dinner, with some mushrooms on the left, edamame (steamed soybeans) in the orange bowl, something delicious that I can't remember in the center (sliced octopus in a savory sauce?), and sashimi and raw meat in the upper right. The two dishes in the right foreground have sauces in them for dipping the fish and meat in. Anyone want to guess want sort of meat that is? It's ... horse(!) Once I overcame my reticence over eating horse meat, I found that it was arguably the best meat I'd ever tasted. Seriously! OK, I know that most of our US readers are probably completely appalled at this point, but I have to say that, if I could ignore the fact that it was a horse I was eating, it was incredibly tender and delicious. It turns out that a lot of horses are raised as meat animals in the Aizu area, through long tradition. I tend to think of horses more as companions than dinner, but have to admit that they taste wonderful.

Here's our hostess/chef Alona, serving some roasted, salted fish to Shinji-san, Sigma's manager of European marketing. The fish were the first thing we saw cooking when we came down to dinner; you can see them in the background of the previous shot above. They were local trout, skewered on thin bamboo spits, which were stuck into the sand of the cooking pit, leaning over the charcoal fire. They were delicious, very slightly on the dry side, but with excellent, delicate flavor. The Japanese way is to eat the entire fish except the fins. I did, and the head was actually quite tasty. :-)

Dinner also involved a number of rounds of local sake. I'm a huge sake fan, it's one of my favorite drinks. Here in the US, only a very few varieties are imported, and they're almost by definition from huge mega-brands, who are equipped to handle international import/export. In Japan, there are hundreds (thousands?) of sake producers, with a number of them in each local area. This might compare to the US phenomena of local brew pubs, each making their own artisan beers, although I believe the sake breweries generally sell their output to restaurants or at retail, vs on-site. We probably had five different sakes this night, all from small, local suppliers, and it was all truly excellent, every one better than any I've had in the US. Each had a unique flavor and mouth feel, distinct from the others; one was even very mildly carbonated.

During dinner, we were also attended by two geisha-san, Mamewaka-san and Tsukino-san. In the US, our image of geisha is rather exotic, perhaps with sexual overtones. In practice, many real geisha-san more closely resemble a favorite aunt than an object of desire. Their social function is to provide interesting conversation and entertainment, although admittedly in some circumstances with flirtatious overtones. In the case of Mamewake-san and Tsukino-san, they were pleasant and engaging dinner companions, and I learned a lot about the lives of modern geisha through them.

After dinner, each performed a traditional Japanese dance. I have to admit that this was a very foreign form of entertainment to me. The dances are very highly structured and symbolic, acting out the stories told in traditional Japanese ballads. It might have helped if I'd known more of the stories that the dances corresponded to, but as it was, it was all pretty opaque to me. I could see, though, that Mamewaka-san and Tsukino-san had devoted a great deal of effort to learning the art form; I appreciated the precision and grace with which they executed their dances. That's Tsukino-san above, performing her dance. (No she doesn't look like someone's aunt; she's quite a young geisha, compared to many.)

The whole experience at Ashina ryokan was exceptional - I highly recommend it if you're ever in the Aizu/Mt. Bandai area of Japan, it's a great example of very traditional Japanese hospitality. If you stop in, tell them that you heard about them from Dave-san at Imaging Resource.

Conclusion

From start to finish, my visit to Sigma's Aizu factory was an extraordinary experience. As I said at the outset, I love factories, and the tour Mr. Yamaki-san took me on was far more in-depth than any I'd previously experienced. As I mentioned at the outset, in the early days, Sigma's stock in trade was inexpensive kit and accessory lenses for film-based SLRs. Following a path he and his father first charted together, though, Kazuto Yamaki is transforming the company into a producer of truly world-class optics, with performance fully meeting the demands of the digital era. We saw some of the first fruits of this in the truly exceptional Sigma 18-35mm f/1.8 DC HSM "A" lens, arguably the best wide-angle lens we've ever tested on SLRgear.com, regardless of price -- primes included. Subsequently, the Sigma 120-300mm f/2.8 DG OS HSM "S" tele zoom turned in a stellar performance as well.

I've been on many factory tours where access was very tightly controlled, to the extent that you wondered whether you were perhaps seeing a Potemkin village version of the production process. In my tour of Sigma's facility, though, I had access to literally every corner of the factory and every element of the process - the only areas I didn't venture into were those inside clean-room environments, and the offer was open to don a bunny suit and tour those as well. As you can gather from all the above, I was highly impressed with what I saw: I think we're going to see a lot more lenses as exceptional as the Sigma 18-35/1.8 and 120-300/2.8 as time goes on.

Many thanks to Mr. Kazuto Yamaki and Mr. Shinji Yamaki for the time, effort, and care they devoted to my visit, and for their gracious hospitality.